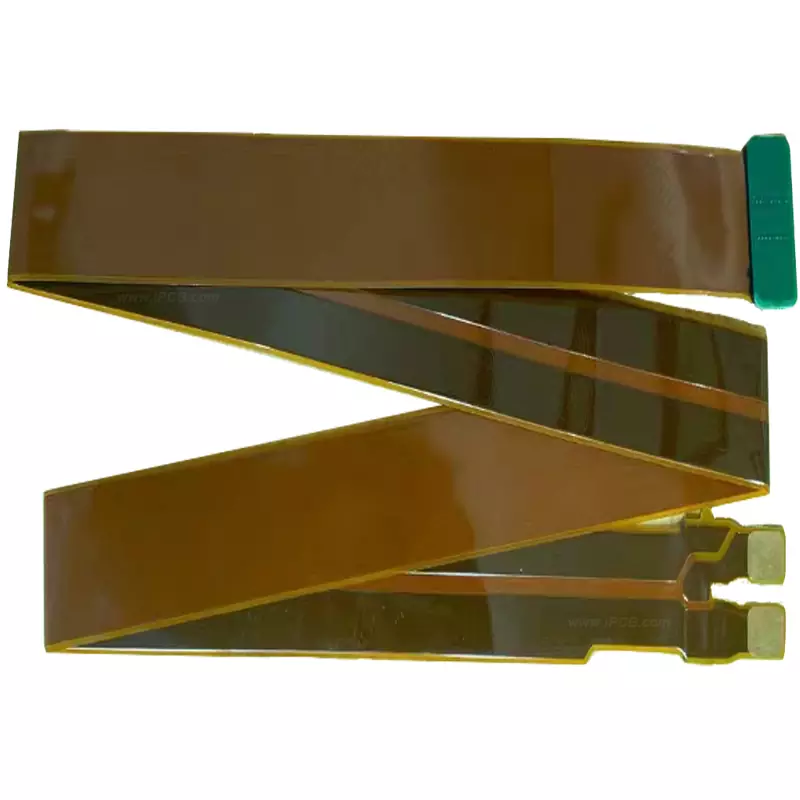

Product Name: Ultra long rigid-flexible PCB

Substrate:High TG FR-4+PI

Layer: 2+2L

Size: Maximum length of 1.2M

FPC thickness: 0.15mm

PCB thickness: 1.6mm

Copper thickness: 0.035mm

Surface treatment: ENIG

Other processes: Golden Finger

Minimum line width/spacing: 6/6 mil

Product application: Communication, Instruments, Aerospace

Because rigid-flexible PCB is a combination of FPC and PCB, the production of rigid-flexible PCB should have both FPC production equipment and PCB production equipment. Firstly, the electronic engineer draws the circuit and shape of the rigid-flexible PCB according to the requirements, and then sends it to the PCB factory that can produce rigid-flexible PCBs. After the CAM engineer processes and plans the relevant documents, the FPC production line is arranged to produce the required FPC, and the PCB production line is arranged to produce the PCB. After these two FPC boards and rigid PCB boards are produced, according to the electronic engineer's planning requirements, the FPC and PCB are seamlessly pressed together by a press machine, and then a series of detailed steps are taken to finally produce the rigid-flexible PCB. A very important step is that rigid-flexible PCBs are difficult and have many detailed issues. Before shipment, a full inspection is generally required to avoid losses due to their high value.

Ultra long rigid-flexible PCB

Rigid-flexible PCB combines the stability of rigid PCB with the three-dimensional assembly of FPC, and has a promising development prospect. The global market size of soft boards accounts for only about 2.8% of the overall circuit board market; But including smartphones, wireless headphones, drones, cars, AR/VR devices, etc., they are all the products with the highest growth rate, and with the increasing number of applications in the future, soft boards are still the products with the most growth momentum.

Smartphone applications are the largest market for soft and rigid PCBs, accounting for approximately 43% of the overall rigid-flexible PCB market. This includes applications such as camera lenses, screen signal connections, and battery modules for smartphones, which have significantly increased demand for soft and hard PCBs. Especially in the application of smartphone camera lenses, as multi lens phones have become a design trend for various mobile phone brands, the increase in demand for software and hardware combination boards, as well as the increase in average unit price, will increase the proportion of the mobile device application market.

The development of Photographic Lens Rigid-Flex PCB is mainly due to the demand for lightweight, thin, and high-density mobile phone lenses, which need to be applied to rigid-flexible PCB. In addition, considering various factors such as placement, direction, signal interference, heat dissipation, and specification settings, coupled with the use of periscope structure design for some lenses due to optical zoom requirements, mobile phone lenses have emerged in multiple different forms in appearance to cope with increasingly stringent space limitations. The technical requirements for the combination of rigid-flexible PCB is more stringent, and their application scope is wider.

The core of rigid-flexible PCB lies in its structural design. It combines a hard PCB with a flexible FPC, and through precise processing techniques, the board maintains hardness where needed and exhibits flexibility where needed. This design greatly expands the application range of circuit boards, allowing designers to boldly innovate product forms while ensuring stable connections of electronic components.

Rigid-flexible PCB also have high surface mount accuracy and lighter weight, which makes them shine in fields such as aerospace and medical devices that require high-precision and lightweight solutions.

Rigid-flexible PCB has brought revolutionary changes to electronic product design with its unique flexibility and robustness. It not only meets the demand for miniaturization and lightweighting in modern electronic products, but also provides unlimited space and possibilities for innovative design. In the future, with the continuous iteration and improvement of technology, rigid-flexible PCB will undoubtedly demonstrate their enormous potential in more fields and become an important force driving technological progress.

Product Name: Ultra long rigid-flexible PCB

Substrate:High TG FR-4+PI

Layer: 2+2L

Size: Maximum length of 1.2M

FPC thickness: 0.15mm

PCB thickness: 1.6mm

Copper thickness: 0.035mm

Surface treatment: ENIG

Other processes: Golden Finger

Minimum line width/spacing: 6/6 mil

Product application: Communication, Instruments, Aerospace

iPCB Circuit provides support for PCB design, PCB technology, and PCBA assembly. You can request technical consultation or quotation for PCB and PCBA here, please contact email: sales@ipcb.com

We will respond very quickly.