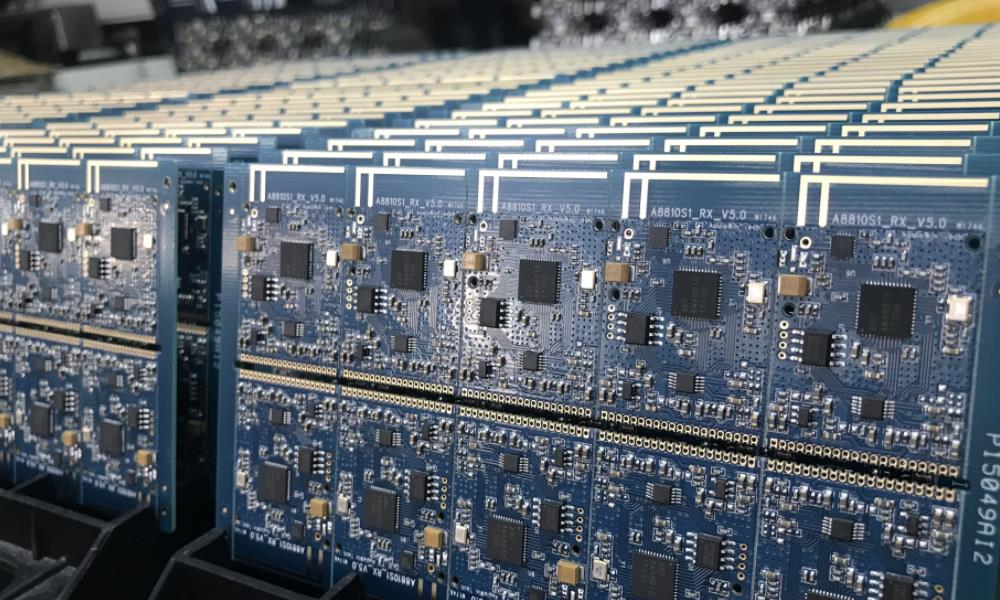

What is PCBA OEM? PCBA OEM is a finished product formed after the PCB bare board has gone through the process of SMT,DIP insert and PCBA testing, quality inspection and assembly, etc. It is the commissioning party who delivers the OEM project to the professional PCBA OEM factory, and then waits for the finished product delivered by the OEM factory according to the time agreed by both parties.

Why choose PCBA OEM?

1.PCBA OEM can effectively save the customer's time cost,the production process control to the professional PCBA OEM, to avoid wasting in IC, resistors, capacitors, diodes and electrodes, and other electronic materials procurement of bargaining and procurement time, while saving inventory costs, inspection time, personnel expenses.

2. In general, although the PCBA OEM factory on the surface of the offer is high, but in fact can effectively reduce the overall cost of enterprises, so that enterprises can focus on their own speciality areas, such as design, R & D, marketing, after-sales service and so on. Next, we will introduce you to the PCBA OEM detailed OEM process:

3.PCBA OEM project evaluation, customers in the design of the product, there is a very important assessment: manufacturability design, which is more critical to the quality control of the manufacturing process.

4.Confirmation of co-operation and signing of contract, both parties decide to co-operate and sign a contract after negotiation.

5.Customers provide OEM information, after customers do the product design well, they will hand over the Gerber file, BOM list and other engineering files to suppliers, who will have special craftsmen to carry out auditing and confirmation, and assess the details of stencil printing, lamination process, insert insertion process and so on.

6.Material procurement, inspection and OEM, customers prepay the PCBA OEM fee to suppliers, suppliers receive the payment and proceed with the procurement of components, and scheduling according to the PMC plan after all materials are prepared.

7.Quality department quality inspection, quality department will be part of the product or full inspection,found defective products for repair.

8.Packaging and after-sales service,all products are packaged and shipped after the completion of the production quality inspection,packaging pipeline is generally used anti-static bag packaging, if the customer has special requirements, will be packaged according to customer requirements, and tracking after-sales service.

PCBA

Why choose IPCB as PCBA OEM?

1.So that you can focus on your core competencies,the whole process of integrated one-stop service,high-speed PCB manufacturing,welding,material supply perfect fit,all-round to help customers achieve from the principle of the programme to the product market. Reduce costs,by reducing the customer's development cycle and the number of development,the customer's actual development of the total cost to the minimum,thereby reducing the cost of the product.

2.You will benefit from our resources as we handle thousands of electronic components every week.We have a specialised electronic components warehouse and a professional purchasing team.

3.We will use professional DFM inspection software to check the manufacturability of your product's design as a whole, and we will also check the match between PCB and material. We will provide professional and effective DFM, DFT and DFA services for your products.

4.We can respond quickly to your changing needs. Our working time and pipeline can flexibly meet your different needs. Your needs are the direction of our efforts and the principles we follow.