Wafer electronics (Jointech) was founded in 2005. It is a global pioneer in semiconductor Internet marketing and a pioneer in the sample center model.

Wafer electronics focuses on the promotion of innovative semiconductor devices, helping original manufacturers to change their marketing methods and accelerate brand and product market awareness.

Wafer electronics is committed to building an information data conversion platform for original manufacturers and customers, insisting on small and medium-sized users as the core, relying on new technologies, using platform data to predict user needs and judge user behavior, and constantly innovating marketing methods, pursuing minimalist and flexible services and ultimate communication efficiency.

JointECH's services cover market research and program exchanges in the early stage of product design, selection recommendations at the beginning of design, free sample testing, technical support, and flexible supply of small batch trial production, spot emergency and mass production scale procurement strategy recommendations, providing users with continuous reliable, fast and flexible supply chain support.

What is a silicon wafer or wafer?

Wafer, also known as silicon wafer, is a thin slice of high-purity crystalline silicon. Silicon wafers are particularly useful in the manufacture of PCBs as substrates for chips. Silicon ranks as the seventh most common element in the entire universe and the second most common element on Earth. Some common silicon-containing materials include sand, quartz, etc. Silicon is one of the main elements in building materials such as bricks, cement, and glass. Silicon is currently the most widely used semiconductor in the field of semiconductor technology.

Although silicon chips may look like metals, they are not exactly metals. Metals are good conductors of electricity, which is the movement of electrons, due to the easily moving "free electrons" between atoms. On the other hand, a pure silicon crystal is almost an insulator; allowing very little current to pass through it. However, the ability of silicon to conduct electricity can be changed by doping it.

Doping is the mixing of small amounts of impurities into silicon crystals to change its behavior and integrate it into a conductor. These impurities used for doping are called dopants.

Silicon itself does not conduct electricity very well; however, it can be precisely doped to control the resistivity to a precise level. Silicon dopants such as nitrogen, indium, aluminum, gallium, and boron are added during the chip manufacturing process. Therefore, to make non-conductive silicon form a semiconductor, the silicon must be turned into a wafer.

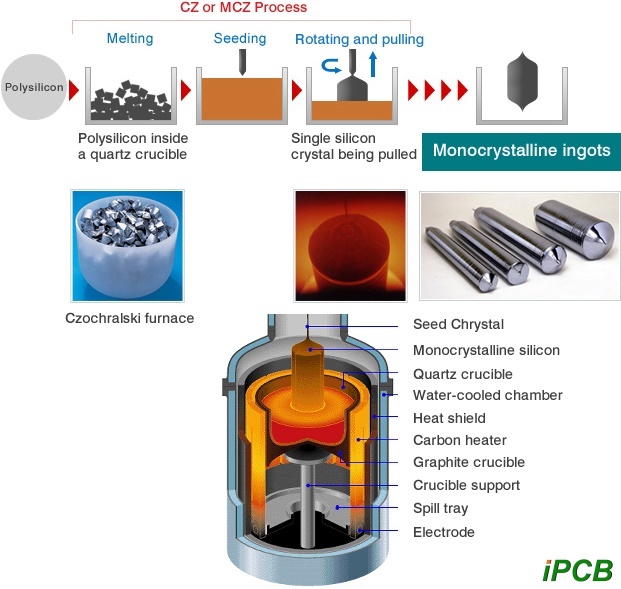

Silicon wafers come in many shapes and sizes, depending on their purpose. Wafers range from 2 inches to 12 inches, with 6 inches, 8 inches, and 12 inches being the most common. They are a key material in integrated circuits, which consist of multiple transistors designed to perform specific tasks. Silicon is a flat disk with a polished mirror-like surface, and it is ubiquitous and found in almost every electronic device. It is a common material for making semiconductors, and the smooth surface of silicon increases its purity, making it suitable for semiconductor devices. The silicon wafer manufacturing methods are the Vertical Bridgeman and Czochralski pull-up methods.

Wafer Applications

As mentioned earlier, the main use of silicon wafers is in integrated circuits (ICs) as it forms a key component of ICs. ICs are a collection of electronic components that work together to perform a specific task. Although different semiconductors have been tested over time, silicon has proven to be a more stable choice. Silicon wafers are used in a variety of gadgets around the world. Its applications span across different types of industries. Here are the details of silicon wafer use cases:

1. Semiconductors

Semiconductors come in different forms and shapes and are the building blocks of various electronic devices. These include transistors, diodes, and integrated circuits. They are manufactured using silicon wafers, which makes them compact and efficient. Due to their ability to handle a wide range of voltages or currents, they are used in optical sensors, power devices, and even lasers.

2. Electronics and Computing

Silicon wafers are widely used in the field of electronics and computing and are the enablers of the digital age. RAM chips are a type of integrated circuit that is made from silicon wafers. This makes silicon wafers important in the computing industry. In addition, silicon wafers are often used to manufacture many devices such as smartphones, automotive electronics, home appliances, and drone technology. In fact, any electronic circuit device has advanced use cases for silicon wafers. New manufacturing technologies and automated processes have made them more effective and efficient.

3. Optics

For optical grading, polished silicon wafers are often manufactured specifically. Silicon wafers are an ideal economical material for reflective optical and infrared (IR) applications. Floating Zone or CZ manufacturing methods are used to manufacture silicon wafers for optical devices. This is because these methods produce fewer defects and are higher than other methods. They are used in micro-optics and fiber optic devices all over the world. An obvious example is the image sensor (CIS) made from complementary metal oxide semiconductor (CMOS) used in cameras.

4. Solar Cells

Solar cells require silicon wafers to improve efficiency and absorb more sunlight. Materials such as amorphous silicon, monocrystalline silicon, and cadmium telluride are often used. Manufacturing processes such as the Floating Zone method can increase solar cell efficiency by nearly 25%. Just like microchips, solar cells follow a similar manufacturing process. The purity and quality level required for solar cells is not as demanding as those used for computing and other electronics.

5. Aerospace

Since its advent, silicon wafers have been widely used in the aerospace field due to their superior performance and quality. Silicon wafers are often used as covering and bonding materials in the aviation industry and to protect and isolate precision tools from extreme temperatures. For decades, it has been a good and trusted choice due to its widespread use and high temperature resistance. Silicone is the most commonly used material in this industry. Chemically cohesive polymers formed on long-chain oxygen as well as silicon components make up the majority of them. Silicon wafers are very helpful for aircraft original equipment manufacturing (OEM) as well as repair, maintenance, and overhaul. Aircraft wear out due to frequent use and need to be replaced.

Wafer electronics are used in almost every element of human life and the advancement of technology. Silicon wafers are the most widely used material in the technology sector due to their stability relative to other semiconductor materials. Not only do they offer a better alternative compared to other metallic substances, but they are also readily available on Earth. It is due to the development and research of semiconductor materials such as silicon, silicon carbide (SiC), germanium, arsenide, and gallium that technological advancements have been possible to such a tremendous degree. Thanks to the invention of ICs powered by silicon wafers, scientists and inventors have used it to streamline large, bulky machines into handheld devices that are easy to carry around. This has become a widespread innovative change in most areas of manufacturing.