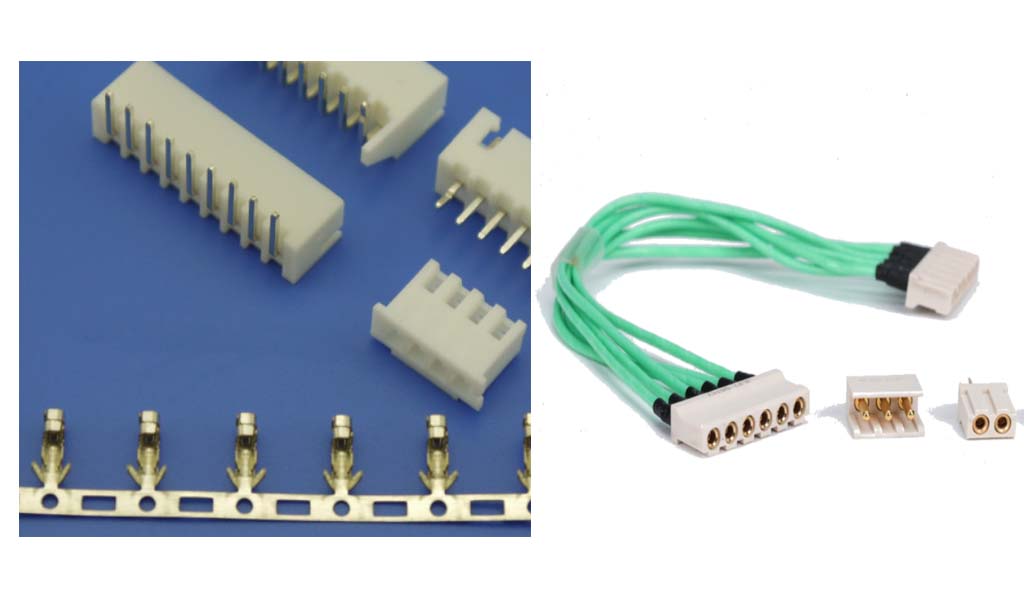

A pcb connectors wire to board is a type of electronic connector used to connect a wire to a printed circuit board (PCB). This connector usually consists of two parts: one part is fixed to the PCB, and the other part allows the wire to be inserted or connected.They are often used to connect external devices or components to the PCB, such as bringing out power, data signals, or control signals to various locations on the PCB. PCB connectors wire to board can be roughly divided into signal wire-to-board connectors and power wire-to-board connectors based on their functions.

Wire-to-board connectors provide power and signals to a printed circuit board (PCB) by connecting a set of discrete wires to the board. There is no standard wire-to-board connector; the various types are specific to the manufacturer that produces them. PCB connectors wire to board can be specified based on a variety of characteristics. These include shell size and material, stack height (the height of the connector from the circuit board) and pin pitch (the distance between the centers of two conductors - usually two pins next to each other). The number of contacts and length can also specify the number of contacts and the number of rows of contacts.

The function of pcb connectors wire to board is mainly to transmit power and signals. According to various uses and requirements, there are countless types of wire to board, most of which are distinguished by the distance between the pins and the transmission current and voltage.

The connector should first consider the number and shape of the connecting wires, and also consider the current and contact voltage in the circuit. The circuit current often determines the wire diameter. How many types of contacts can be selected based on different wire diameters? The contacts need to match not only the conductor diameter but also the diameter of the insulating plastic. When selecting the contact plating, you need to understand the current and contact pressure data and the environment in which the connector is used. Different types of connectors are suitable for different currents and contact pressures.

The number of pins is also a factor to consider. Unexpected contact pressure will be generated when plugging and unplugging the connector. This is because each contact will make contact, so the higher the number of pins, the greater the contact pressure. Gold plating can reduce the contact pressure of each contact point, but tin plating cannot. Tin-plated sheets require relatively high contact pressure, so the maximum number of pins allowed is less than the number of gold-plated pin cores.

Commonly used connection methods with PCB: SMT/DIP

——SMT (Surface Mount Termination)

SMT (Surface Mounting) is a method of fast connection of board-end Conn. The connection part of the board end is pre-filled with paste tin, and then the Conn is accurately placed on the circuit of the board end by a special machine (chip mounter), and then connected after high temperature (reflow soldering/TR furnace). Therefore, the plastic and electroplating of the SMT Conn must be able to withstand high temperatures. Its products require the terminal pin position (True Position) and the terminal coplanarity (Co Planarity)

—DIP (Through-hole Type)

DIP (Direct Insertion Assembly) is a way of connecting the board end Conn. The connecting pin of the Conn will be longer to be inserted into the hole on the corresponding board and then soldered by immersion tin (wave soldering). Its products require the terminal pin position (True Position)

PCB connectors wire to board are efficient and cost-effective. They are used in various applications, including automotive, industrial, telecommunications, lighting and display, commercial electronic equipment and home appliances.

At present, the world's top manufacturers of PCB connectors wire to board are mainly TycoElectronics, Amphenol, Molex, FCI, JAE, JST, Hirose, Kyocera, TYCO, FCI, ACES, etc.