The HDI PCB process is based on traditional double-sided boards as the core board, which are continuously stacked and laminated. This type of circuit board, which consists of a continuously stacked process, is also known as Build up Multilayer (BUM). Compared to traditional circuit boards, HDI PCBs have advantages such as being light, thin, short, and small.

The interlayer electrical interconnection of HDI PCBs is achieved through conductive through-hole, buried hole, and blind hole connections. Its structure is different from ordinary multi-layer circuit board processes. In the HDI PCB circuit board process, a large number of micro buried blind holes and laser direct drilling are used, while the standard PCB process usually uses mechanical drilling, so the number of layers and aspect ratio are often reduced compared to traditional standard PCBs. Compared to regular PCBs, the most significant feature of HDI PCBs is higher circuit density, smaller size, and lighter weight.

IPCB circuit provides high-precision HDI circuit board models and batch manufacturing, supporting fast milling of HDI PCB models. The following is the process capability table for iPCB circuits. Please feel free to contact us.

HDI PCB Definition

1. HDI hole: refers to a through hole made by a laser drilling machine, also known as an H-hole, blind hole, or lightning perforation.

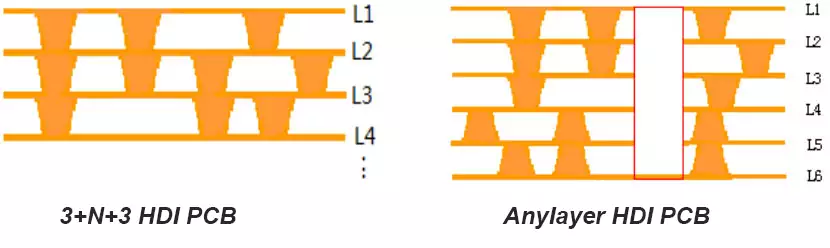

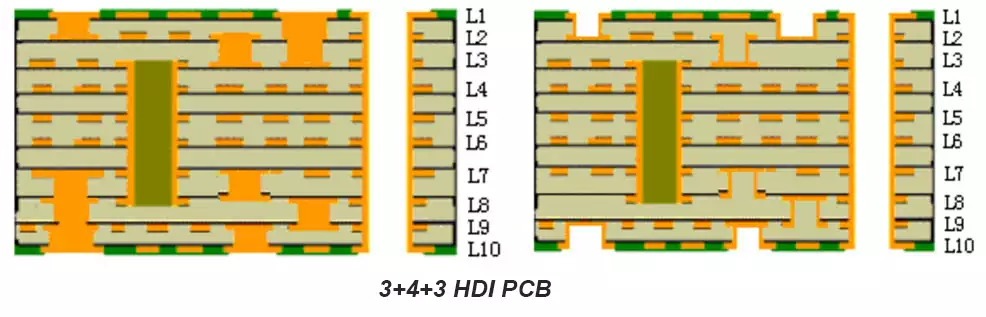

2. Third order HDI PCB: Refers to a PCB that contains at least L1/2/3/4 or L1/4 third order HDI holes (the board may also have first/second order HDI holes, or may not have first/second order HDI holes). The structure of the board is usually expressed as 3+X+3, and so on for multi-stage boards.

3. Multi stage board HDI PCB: Refers to HDI PCBs of third order or higher, usually expressed as n+X+n, (n ≥ 3).

4. Anylayer arbitrary interconnect HDI circuit board: refers to a PCB board with only one HDI hole per adjacent layer. Usually, the structure of the board is expressed as n+2+n, which starts with a double-sided board and is stacked accordingly for pressing and drilling laser holes.

5. The definitions of various HDI layers in third-order and Anylayer HDI PCB structures are as follows:

HDI circuit board structure

Production process L04/05, L06/07 for third-order blind hole design

Cutting → IDF (pre-treatment → film application → exposure → DES) → IAOI

Production process L03/08 for stepped three-stage blind hole design

L04/05, L06/07 browning → L03/08 board arrangement/lamination → CFM drilling target/pressing plate post-treatment → copper reduction → secondary browning → LDD laser drilling → mechanical drilling → grinding → debonding → copper deposition flash plating → full board electroplating → L03/08 IDF (pre-treatment → film pasting → exposure → DES) → L03/08 OAOI

The production process of filling hole third-order blind hole design (L03/08)

L04/05, L06/07 browning → L03/08 board arrangement/lamination → CFM drilling target/pressing plate post-treatment → copper reduction (1) → secondary browning → LDD laser drilling → grinding plate → degumming → copper deposition flash plating → horizontal hole filling electroplating → X-RAY drilling target hole → copper reduction (2) → mechanical drilling → grinding plate → degumming → copper deposition flash plating → full board electroplating → L03/08 IDF (pre-treatment → film pasting → exposure → DES) → L03/08 OAOI

Production process L02/09 for stepped three-stage blind hole design

L02/09 browning → L02/09 board arrangement/lamination → CFM drilling target/pressing plate post-treatment → secondary browning → LDD laser drilling → plate grinding → debonding → copper deposition flash plating → full plate electroplating → L02/09 IDF (pre-treatment → film pasting → exposure → DES) → L02/09 inner layer AOI

Production process L01/10 for stepped three-stage blind hole design

L01/10 browning → L01/10 plate arrangement/lamination → CFM drilling target/pressing plate post-treatment → copper reduction → secondary browning → LDD laser drilling → mechanical drilling → plate grinding → debonding → copper deposition flash plating → full plate electroplating → L01/10 ODF (pre-treatment → film pasting → exposure → DES) → L01/10OAOI

Production process L02/09 for filling type third-order blind hole design

L02/09 browning → L02/09 board arrangement/lamination → CFM drilling target/pressing plate post-treatment → secondary browning → LDD laser drilling → plate grinding → debonding → copper deposition flash plating → horizontal hole filling electroplating → L02/09 IDF (pre-treatment → film pasting → exposure → DES) → L02/09 inner layer AOI

The production process of filling hole type third-order blind hole design (L01/10)

L01/10 browning → L01/10 plating/lamination → CFM drilling target/pressing plate post-treatment → copper reduction (1) → secondary browning → LDD laser drilling → grinding plate → degumming → copper deposition flash plating → horizontal hole filling electroplating → X-RAY drilling target hole → copper reduction (2) → mechanical drilling → grinding plate → degumming → copper deposition flash plating → full plate electroplating → L01/10 ODF (pre-treatment → film pasting → exposure → DES) → L01/10 OAOI

Anylayer's production process (taking 10 layers of Anylayer as an example)

{L5/6 cutting - L5/6 mechanical drilling (drilling tool holes) → gong board trimming (rounded corners) → L5/6IDF (using wet film for CFM window opening) or secondary browning → L5/6 laser drilling - L5/6 debonding - L5/6 copper deposition flash plating - L5/6 horizontal hole filling electroplating - L5/6IDF (pre-treatment - film pasting - exposure DES) - L5/6AOI} → {L4/7 browning - layout plate pressing plate - CFM drilling target hole - pressing plate post-treatment - secondary browning - laser drilling (LDD) → Grinding plate - Glue removal - Copper flash plating - Horizontal hole filling - IDF (pre-treatment film pasting exposure DES) - IAOI} - {L3/8 browning - Plate pressing plate - CFM drilling target hole - Plate post-treatment - Secondary browning - Laser drilling (LDD) - Grinding plate - Glue removal - Copper flash plating - Horizontal hole filling - IDF (pre-treatment film pasting exposure DES) - IAOI}-- {L2/9 browning → Plate pressing plate → CFM drilling target hole → Post treatment of plate pressing plate → Secondary browning → Laser drilling (LDD) → Grinding plate → Glue removal → Copper deposition flash plating → Horizontal hole filling → IDF (pre-treatment film pasting exposure DES) → IAOI} → L1/10 browning → Plate pressing plate → CFM drilling target hole → Post treatment of plate pressing plate → Copper reduction → Secondary browning → Through blind hole folding electroplating (LDD) → Grinding plate → De gluing → Copper flash plating → Horizontal hole filling electroplating → XRAY drilling target hole → Copper reduction (2) → Mechanical drilling → Grinding plate → De gluing → Copper flash plating → Full plate electroplating)/Through blind hole plating (Laser drilling (LDD) → Mechanical drilling → Grinding plate → De gluing → Copper flash plating → Vertical hole filling electroplating → Horizontal hole filling electroplating) → Mechanical drilling → ODF (Pre treatment - Film pasting - Exposure DES) → OAOI}

The post process follows a typical production process, which involves coating and testing the surface of the outer board

Green Oil → Characters → Nickel Gold Deposition → Impedance Testing → Milling Shape → ETEST → Final Inspection → FQA Sampling → Packaging

At present, the HDI PCB process capability technology of iPCB circuits has exceeded the maximum layer count of 38 layers, with blind hole orders ranging from 1 to 7 or any interconnected HDI of Anylayer circuit board, with a minimum aperture of 0.05mm.