iPCB has a complete production process for FR-4 single-layer, FR-4 double-layer, and FR-4 multi-layer circuit boards. We provide stable and high-quality products, and provide customers with PCB circuit boards that meet their requirements for a long time, making us a reliable partner for customers.

We provide customers with lead-free or halogen-free PCBs(HF PCB).

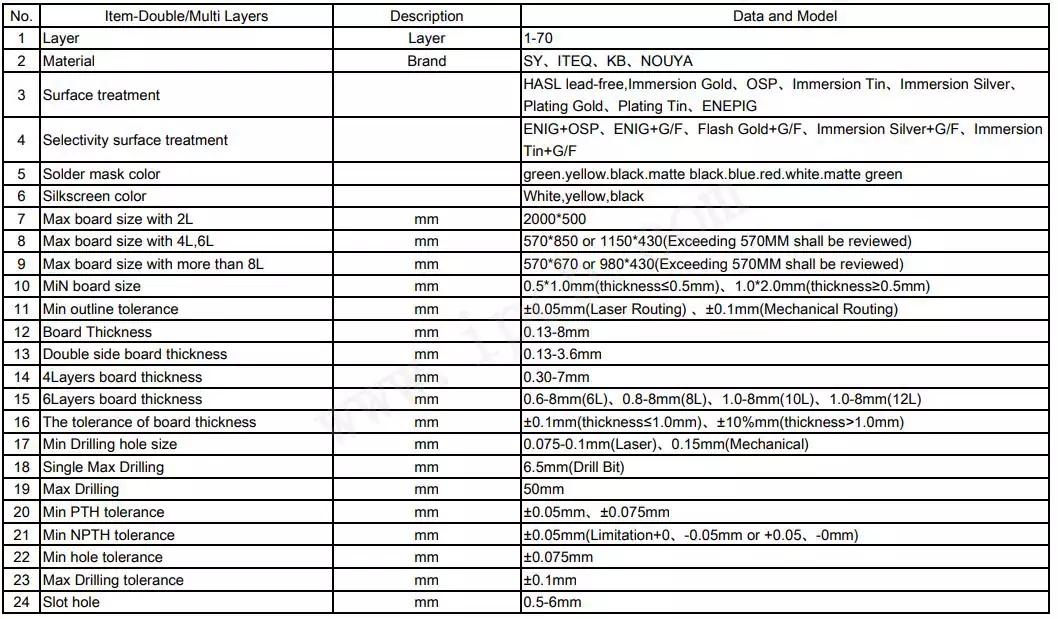

FR-4 PCB capability

FR-4 is the code of a flame resistant material grade, which means a material specification that the resin material must be able to extinguish itself after burning. It is not a material name, but a material grade.

Therefore, there are many kinds of FR-4 materials currently used for general circuit boards, but most of them are composites made of so-called Tera Function epoxy resin, filler and glass fiber.

FR-4 epoxy glass fiber cloth substrate is a kind of substrate with epoxy resin as adhesive and electronic grade glass fiber cloth as reinforcement. Its adhesive sheet and inner core thin copper clad laminate are important substrates for manufacturing multilayer printed circuit boards.

The mechanical properties, dimensional stability, impact resistance and moisture resistance of epoxy glass fiber cloth substrate are higher than those of paper substrate. Its electrical performance is excellent, its working temperature is high, and its performance is less affected by the environment. In terms of processing technology, it has great advantages over other resin glass fiber cloth base plates. This kind of product is mainly used for double-sided PCB, with large consumption. Epoxy glass fiber cloth substrate, the most widely used product model is FR-4.

Our company can use commonly used FR-4 materials, high TG FR-4 materials, high speed FR-4 materials, and TG250 polyimide resin high-temperature materials, such as SH260, VT901, 85N. SH260 and VT901 materials are in stock.

Materials: FR4, high TGFR4, high-speed FR4, high-frequency materials, halogen-free materials, aluminum based, copper based, FPC, ceramic materials

Test: open/short circuit test, impedance test, solderability test, thermal shock test, metallographic microsection analysis

Soldering resistance color: green, black, blue, white, yellow, purple

Character color: white, yellow, black

Surface technology: HASL, Lead-free HASL, Immersion gold(ENIG), Gold Finger, OSP, Immersion Silver, OSP + ENIG, Immersion Tin, Flash Gold

Other processes: golden finger, blue glue, blind hole

The above are some process PCB capability parameters, and we are willing to provide PCB technical support.