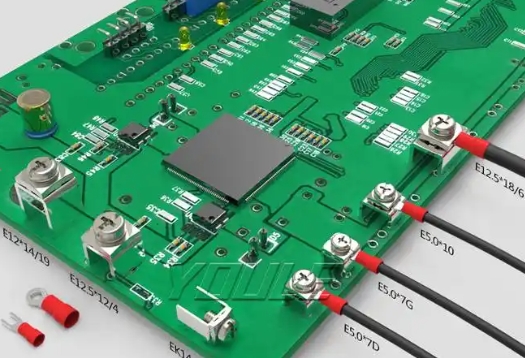

Whether it is a circuit board, metal frame or building component, substrate mounting screws have the important functions of fixing, supporting and conducting.

The core role of substrate mounting screws

1. Fixing and supporting

Substrate mounting screws firmly connect substrates of different materials or thicknesses through thread engagement to prevent loosening or displacement caused by vibration, impact or gravity.

2. Conductivity and heat dissipation

In electronic equipment, some screws (such as copper or nickel-plated screws) can simultaneously perform conductive or heat dissipation functions to optimize equipment performance.

3. Structural reinforcement

In the field of construction or machinery, screws improve the rigidity and stability of the overall structure through pre-tightening force.

Classification and selection of substrate mounting screws

1. Classification by material

Carbon steel screws: low cost, high strength, but easy to rust, suitable for dry environments.

Stainless steel screws: strong corrosion resistance, suitable for humid or outdoor environments (such as 304/316 stainless steel).

Copper screws: excellent conductivity, often used for grounding electronic equipment or high-frequency signal transmission.

Titanium alloy screws: lightweight, high strength, suitable for aerospace or high-end equipment.

2. Classification by thread type

Self-tapping screws: directly tap into the pcb substrate without pre-drilling, suitable for thin plates or soft materials.

Machine thread screws: need to be used with nuts, suitable for high-strength connections.

Set screws: fixed by top tightening force, no thread matching, suitable for precision instruments.

3. Selection principles

Select the hardness and corrosion resistance of the screws according to the substrate material.

Consider the pre-tightening force of the screws to avoid deformation of the substrate due to over-tightening.

Preferably choose standard parts for easy subsequent maintenance and replacement.

Installation tips for substrate mounting screws

Pre-drilling matching

Select a suitable drill bit according to the screw diameter (such as a 2.8mm drill bit for M3 screws) to ensure full thread engagement.

Thread lubrication

Apply a small amount of lubricant (such as thread locker) before installation to increase the pre-tightening force and prevent loosening.

Torque control

Use a torque wrench to set the precise torque value to avoid over-tightening or over-loosening (such as the recommended torque for M3 screws: 1.5-2. Nm).

Installation sequence

Install from the center of the substrate to the edge step by step to reduce stress concentration; after installation, check whether the screws are exposed 1-2mm from the surface of the substrate to ensure safety.

Maintenance and inspection of substrate mounting screws

Regular inspection

Observe whether the screws are rusty or deformed, and replace them if necessary.

Anti-loosening measures

Use anti-loosening washers, thread lockers, etc. to avoid loosening due to vibration.

Environmental adaptability

Choose stainless steel screws in humid environments, and galvanize or nickel-plated screws are preferred for outdoor equipment.

Future trends: Innovative direction of substrate mounting screws

Material upgrade

Develop lighter and stronger new alloy screws to improve durability.

Intelligent design

Develop screws with sensors or intelligent locking functions to monitor preload in real time.

Environmental protection

Promote screws with recyclable materials or non-toxic coatings to reduce the impact on the environment.

Although the substrate mounting screws are small, they carry huge responsibilities. From selection, installation to maintenance, every step needs to be treated rigorously. Whether it is an engineer, installer or DIY enthusiast, only by mastering the correct technology and methods can a solid guarantee be provided for the stable operation and safety of the equipment.