There are many types of circuit boards that have been developed so far, but most of them can be classified into two types: rigid boards and flexible boards (FPC).

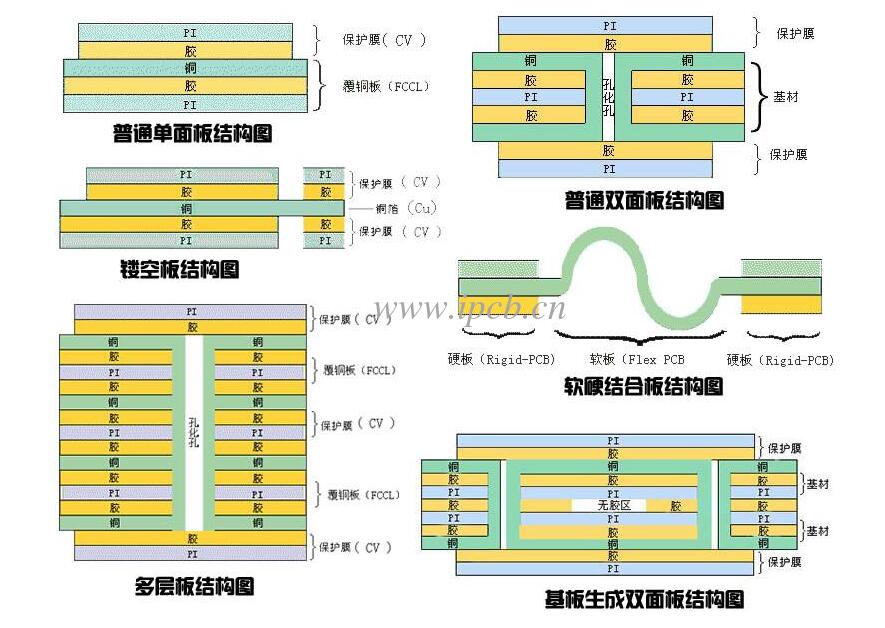

FPCs are also known as flexible circuit boards. Today we will introduce the structure of FPC. Generally speaking, flexible boards are classified according to the number of layers and thickness of the conductive copper foil, which can be divided into single-layer flexible boards, double-layer flexible boards, multi-layer flexible boards, and double-sided flexible boards, and their structures are also different, the following section introduces the different properties of where they are.

Flexible Boards Structure

Structure of Single Layer Flexible Board

This is the simplest structure of the flexible board, usually with the substrate + transparent adhesive + copper foil one set of purchased raw materials, and protective film + transparent adhesive is Another kind of purchased raw materials; first of all, the copper foil has to be etched and other crafts process to get the required circuit, the protective film has to be drilled to expose the corresponding pads, cleaned, and then rolled to combine the two, and then in the exposed part of the pads electroplated with gold or tin, etc., for protection, so the large PCB board is ready.

In this way, the large board is ready, and then it needs to be stamped into small boards of corresponding shapes. There is also no protective film and directly printed on the copper foil soldermask, so the cost will be lower, but the mechanical strength of the circuit board will deteriorate. Unless the strength requirements are not high but the price needs to be as low as possible, the application of protective film method.

Double Layer Flexible Board Structure

When circuits are too complex to be routed through a single layer or when copper foils are required for ground masks, it is necessary to use a double layer or multi-layer flexible board. Structure of Multilayer FPC: The most typical difference between Multilayer FPC and Single Layer FPC is the addition of perforated structure to connect the layers of copper foil, generally the first process of substrate+transparent adhesive+copper foil is to make the perforation.

First of all, the holes are drilled in the substrate and the copper foil, and then plated with a certain thickness of copper after cleaning, so that the perforation will be ready, and then the subsequent processes are almost the same as the Single Layer FPC.

Structure of Multilayer Flex pcb

Multilayer FPC has soldering pads on both sides, which are mainly used for connecting with other PCB. Although it is similar to the structure of single-layer flexible board, but the production process is very different, its raw materials are copper foil, protective film + transparent adhesive, first of all, according to the requirements of the location of the soldering pads in the protective film drilling holes, and then the copper foil pasted, and then corrosion out of the pads and wires, and then pasted on the other drilled holes in the protective film can be.

Flexible board it these types of structure although different types, but many of the production process has the same place, just in some basic places added different processes, used to respond to different areas.