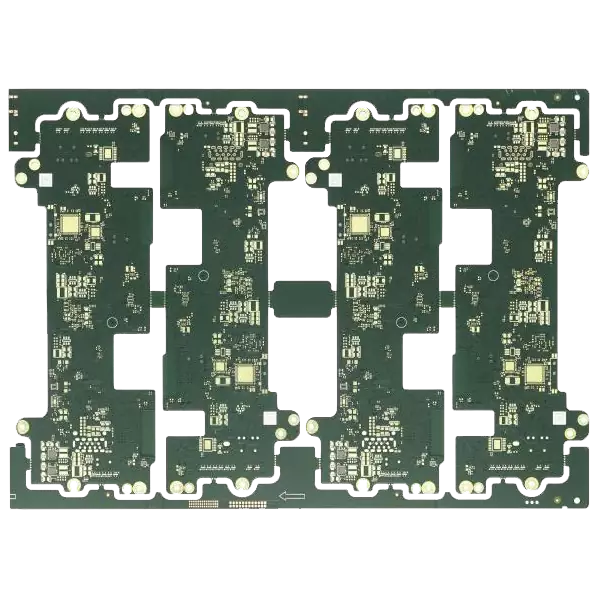

Product: HDI Circuit Board

Material: ITEQ IT180

Layer: 3+6+3

Color: Green/White

Finished thickness: 1.2mm

Copper thickness: 1oz

Surface treatment: immersion gold + OSP

Minimum line width: 3mil

Minimum spacing: 3mil

Impedance requirement: Yes

Application: VR devices

HDI PCB (High Density Interconnect Circuit Board) is a circuit board with high-density interconnect characteristics, which achieves fine connections between circuits through the use of advanced process technology. This technology has higher wiring density, smaller aperture, and thinner board thickness, thereby improving the performance and reliability of circuit board. HDI Circuit Board is widely used in consumer electronics products such as smartphones, tablets, and wearable devices, providing strong support for the lightweight and high-performance development of products.

HDI Circuit Board is a printed circuit board with high integration, high precision, and miniaturization. It adopts advanced manufacturing technology to tightly assemble multiple electronic components together, achieving fast transmission and efficient heat dissipation of the circuit.

The difference between HDI PCB and standard PCB

1. HDI circuit board typically have more layers, allowing for higher integration and more complex circuit designs.

2. The manufacturing process of HDI circuit board is more complex, and HDI PCB use technologies such as micro hole filling and metallization holes to achieve high-speed and high reliability signal transmission.

3. HDI circuit board have higher dimensional accuracy, which is beneficial for the miniaturization and compact layout of electronic components.

4. The high integration and miniaturized design of HDI PCB make the product smaller in size and lighter in weight, which is conducive to the development of electronic products towards lightweight.

2. The micro hole filling and metallization hole technology of HDI PCB reduces the delay and loss of signal transmission, and improves the response speed of the circuit.

3. The advanced manufacturing process and materials of HDI PCB board ensure the long-term stable operation of the circuit and reduce the failure rate.

HDI circuit board, as an advanced technology in the PCB field, has been widely used in electronic products such as smartphones due to its advantages of high integration, high precision, and miniaturization. Compared with standard circuit board, HDI circuit board have significant advantages in terms of size, transmission speed, and reliability, and are expected to continue leading the development trend of the PCB industry.

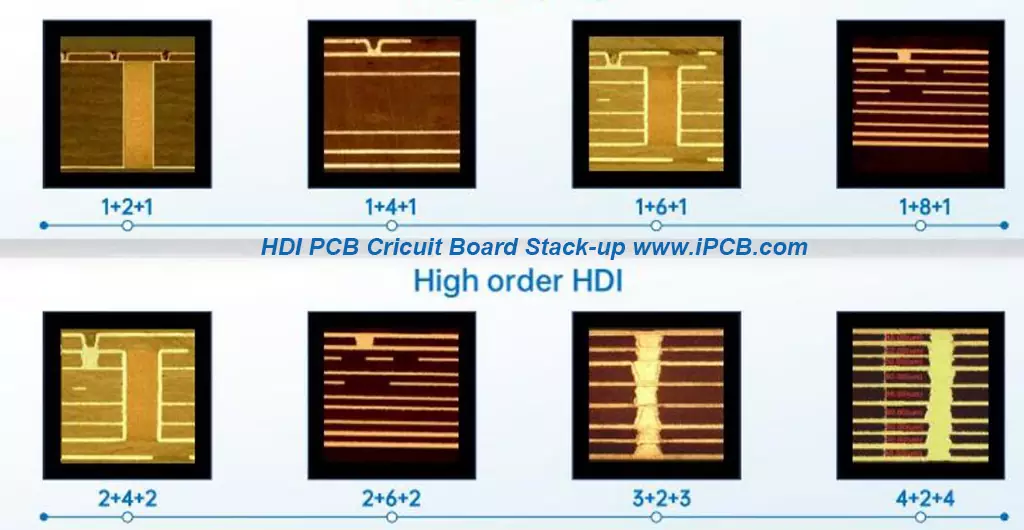

HDI PCB Cricuit Board Stack-up

Application of HDI Circuit Board

With the booming development of emerging technologies such as 5G communication, Internet of Things (IoT), artificial intelligence (AI), and autonomous driving, higher requirements have been put forward for the processing power, data transmission speed, and energy efficiency ratio of electronic devices. The market demand for HDI circuit board, as a key technology to enhance these performances, is continuously growing.

In the field of mobile communication, HDI circuit board are the key to achieving high performance and portability for products such as smartphones and wearable devices that have strict limitations on size and weight.

Automotive Electronics: The advancement of autonomous driving technology requires vehicles to be equipped with more sensors and processors, and HDI circuit board can effectively support the integration of complex electronic systems.

Data centers and cloud computing: In order to improve data processing speed and reduce energy consumption, servers and data centers are widely adopting high-performance HDI circuit board.

Medical equipment: Precision medical devices have extremely high requirements for miniaturization and reliability, and HDI circuit board technology can meet these needs.

HDI PCB circuit board, with their unique technological advantages, are gradually becoming the mainstream trend in the electronic manufacturing industry. It not only represents the advanced level of current electronic technology, but also the cornerstone of future intelligent technology development. With the continuous advancement and innovation of technology, HDI circuit board will demonstrate unlimited potential in more fields, promoting the development of electronic devices towards smaller, faster, and smarter directions.

Product: HDI Circuit Board

Material: ITEQ IT180

Layer: 3+6+3

Color: Green/White

Finished thickness: 1.2mm

Copper thickness: 1oz

Surface treatment: immersion gold + OSP

Minimum line width: 3mil

Minimum spacing: 3mil

Impedance requirement: Yes

Application: VR devices

iPCB Circuit provides support for PCB design, PCB technology, and PCBA assembly. You can request technical consultation or quotation for PCB and PCBA here, please contact email: sales@ipcb.com

We will respond very quickly.